Understanding the Superiority of PU Insulation

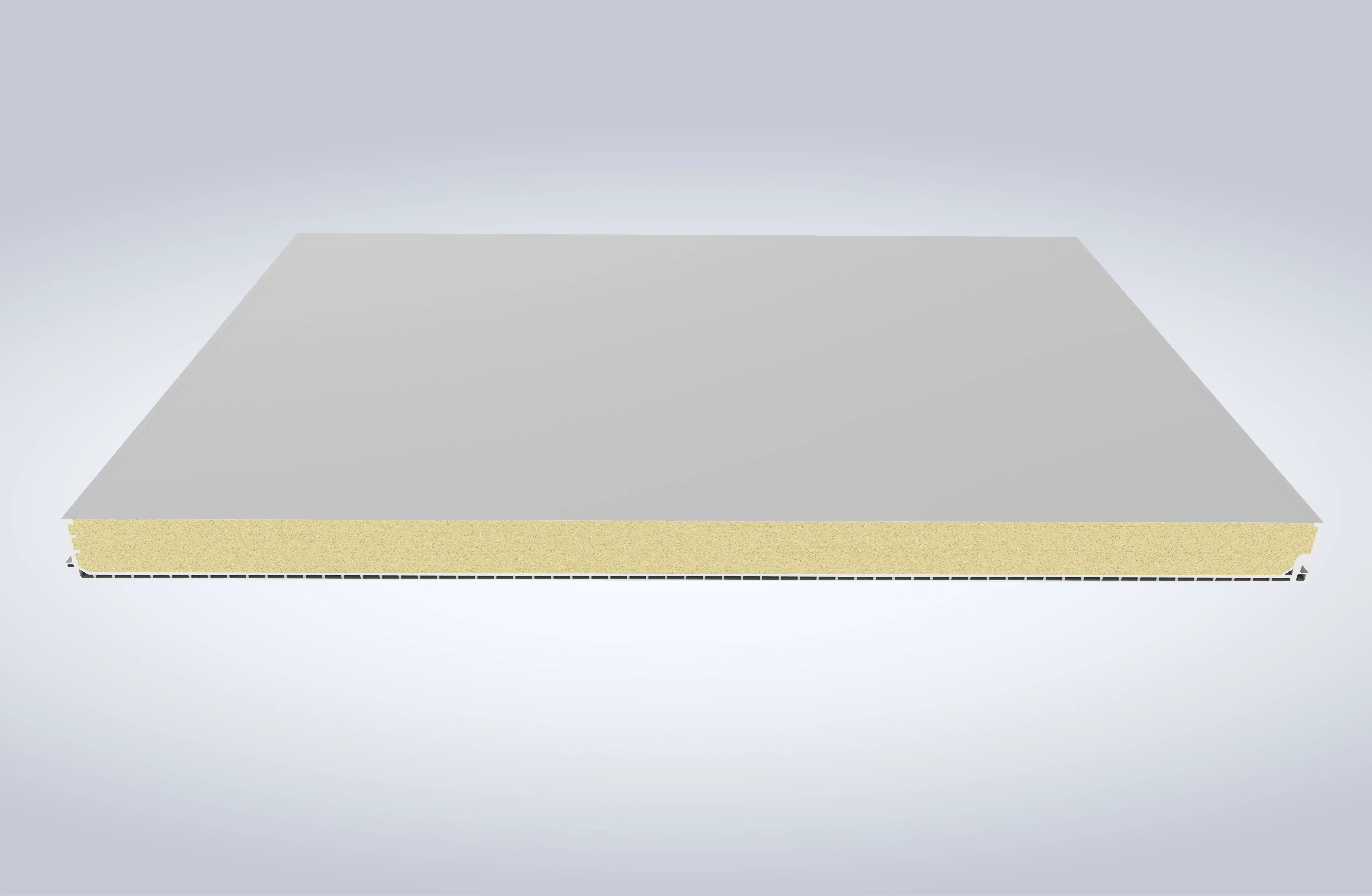

At the heart of these revolutionary ceiling systems is polyurethane foam, a material celebrated for its exceptional thermal insulation properties. The core of a PU insulation panel is engineered to provide an incredible barrier against temperature fluctuations. This high-performance core minimizes heat transfer, meaning buildings stay cooler in the summer and warmer in the winter, leading to significant reductions in energy consumption and lower utility bills. This is not just about comfort; it's a strategic investment in the building's operational efficiency. Unlike traditional insulation materials, PU foam offers a higher R-value per inch, providing superior insulation without requiring excessive thickness. This allows for more streamlined designs and preserves valuable interior space. Furthermore, these panels are designed with structural integrity in mind, offering a lightweight yet robust solution that adds to the building's overall stability without overburdening the frame.

The Hallmarks of a Premier PU Insluation Ceiling Manufacturer

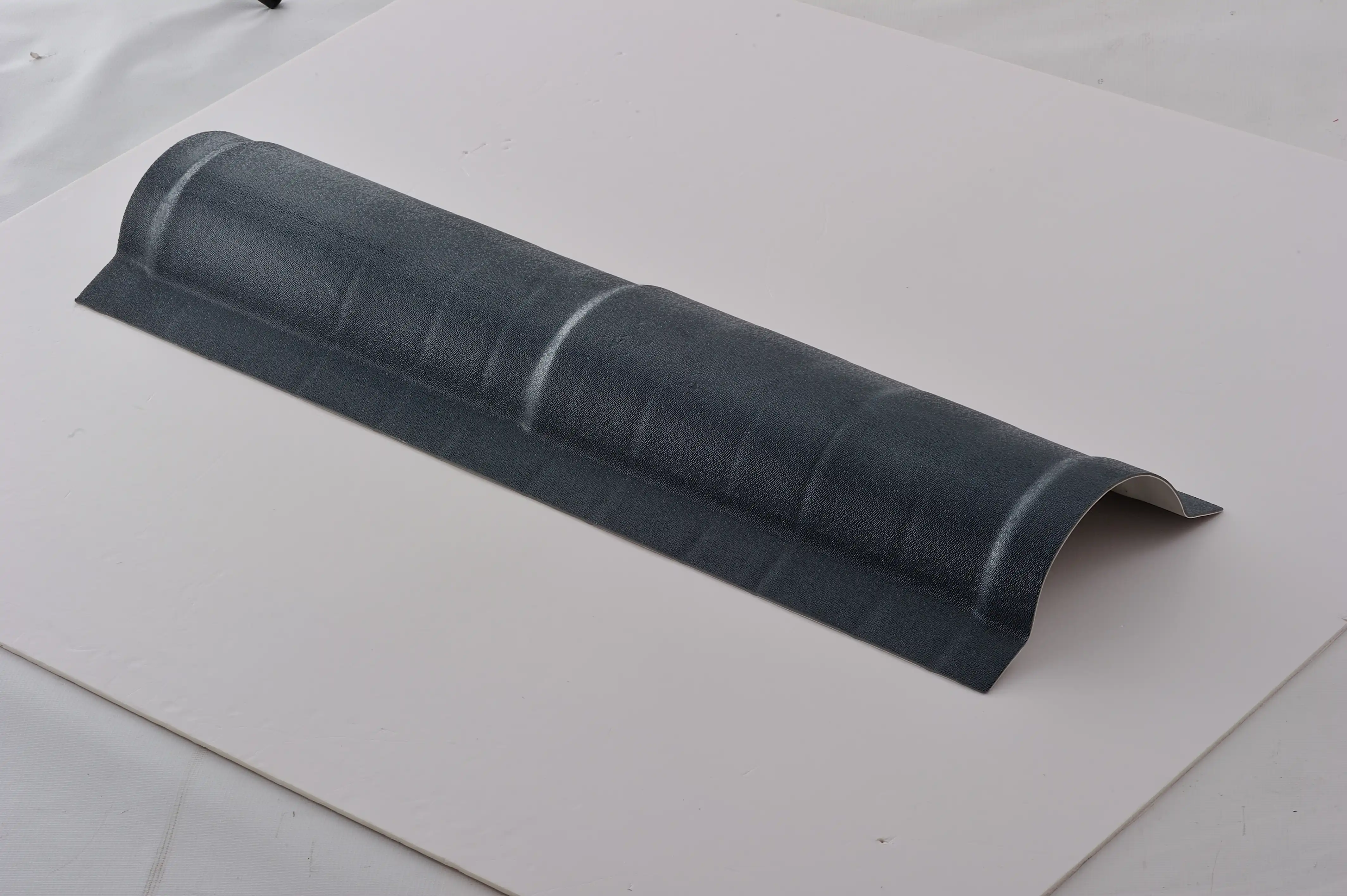

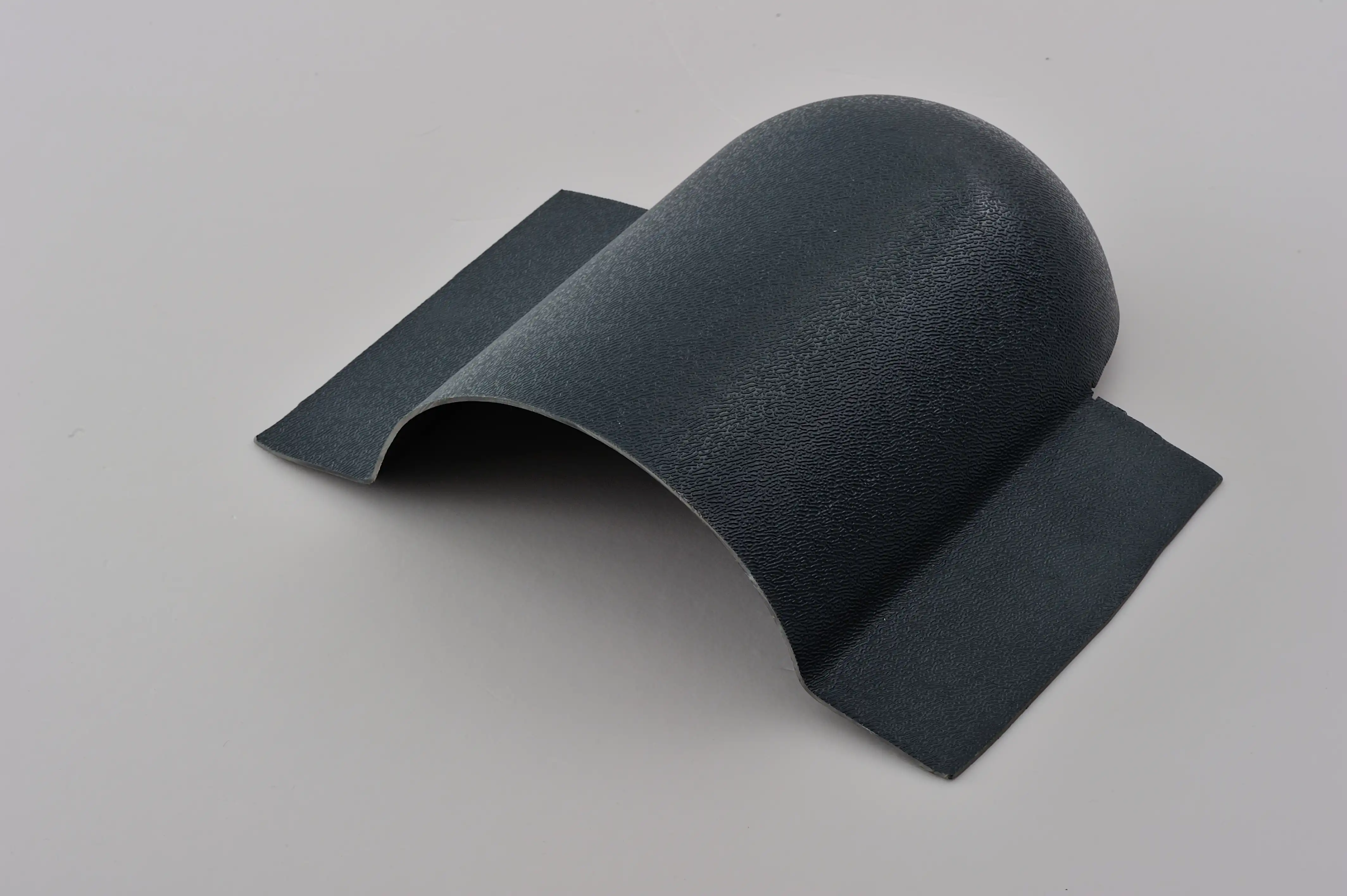

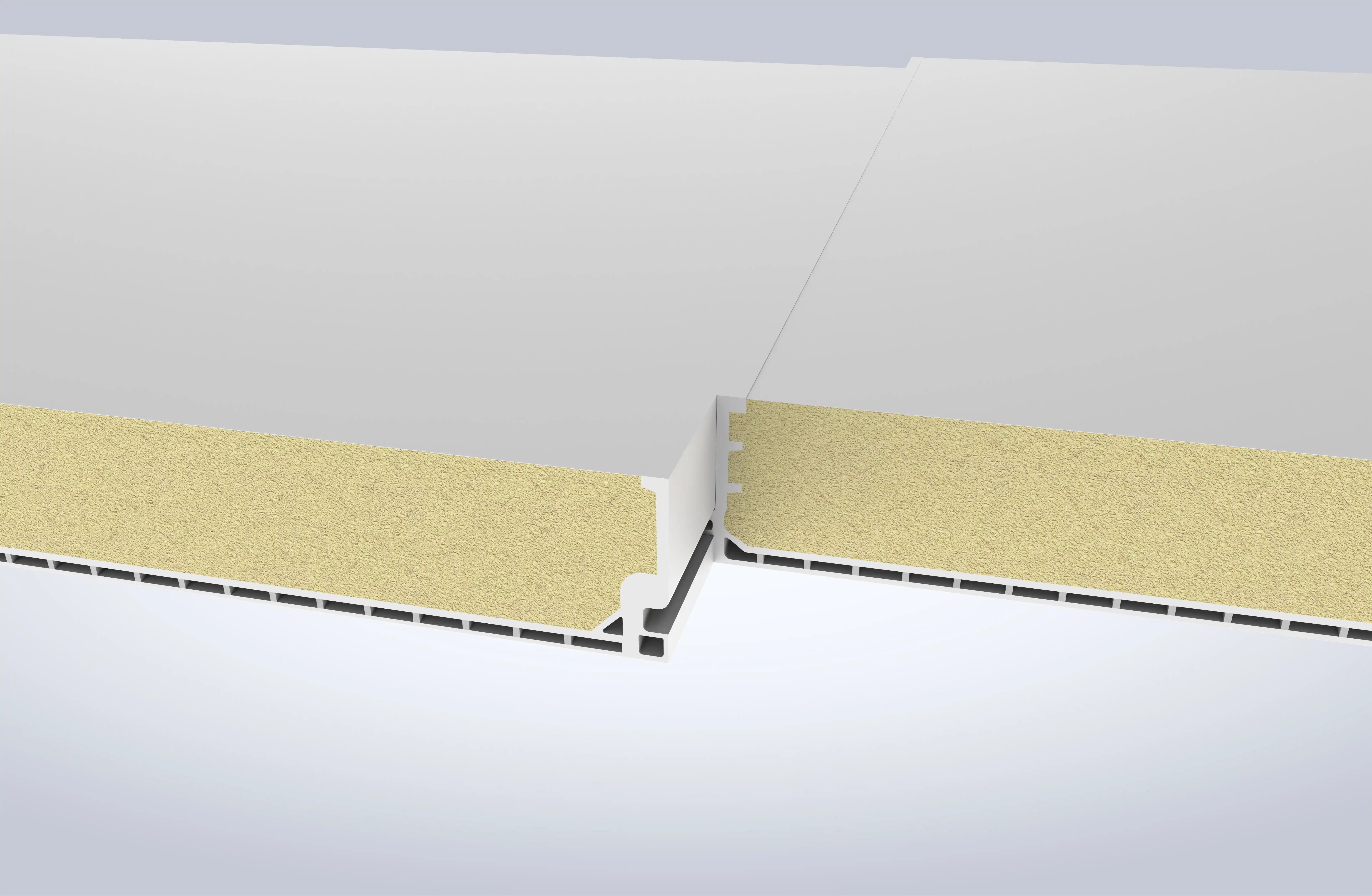

Choosing the right PU Insluation ceiling manufacturer is paramount to realizing the full potential of this technology. Leading manufacturers, such as Zhejiang Honch Technology Co., Ltd., operate at the forefront of innovation, employing precision engineering and state-of-the-art processes. A premier manufacturer invests in a robust multi-layer construction, often featuring an exterior of premium-grade material like PVC for durability and an exquisite finish, bonded to the specialized polyurethane foam core. An essential feature to look for is an advanced interlocking design, such as a tongue-and-groove system. This innovative mechanism guarantees a seamless installation and creates tightly sealed joints, which are crucial for eliminating cold bridges and maximizing insulation prowess. Sourcing directly from a distinguished manufacturer also provides access to products backed by internationally recognized certifications, such as ISO9001 and EU CE, offering an undeniable assurance of quality, safety, and reliability.

Selecting a Reliable PU Insluation ceiling supplier

A project's success often hinges on the reliability and expertise of its partners, and this is especially true when choosing a PU Insluation ceiling supplier. A great supplier does more than just deliver a product; they provide a comprehensive service that supports the project from procurement to installation. This includes robust logistics to ensure materials arrive on-site, on time, and in perfect condition. They offer technical expertise, helping clients select the precise panel specifications, thickness, and finishes best suited for their application. A knowledgeable supplier acts as a vital link between the factory and the construction site, facilitating clear communication and resolving any potential challenges swiftly. Their role is to ensure a smooth, efficient, and successful integration of the insulation system into your build.

Diverse Applications of PU Insulated Ceiling Panels

The versatility of PU insulated ceilings makes them an ideal choice for a vast array of applications. In corrosive industrial environments, such as chemical plants or coastal facilities, the durable exterior surfaces protect the structure from harsh elements while the insulation core maintains critical temperature control for sensitive processes. For agricultural establishments like barns or storage facilities, these panels provide a stable climate, protecting livestock and produce while offering surfaces that are easy to clean and maintain. In the residential sector, homeowners benefit from enhanced energy efficiency, improved acoustic comfort, and a sleek, modern aesthetic. Commercial buildings, from warehouses to office complexes, leverage the rapid installation and long-term performance of these panels to minimize construction timelines and reduce ongoing operational costs. This adaptability makes PU ceilings a smart, functional, and stylish solution for nearly any architectural challenge.

Commitment to Sustainability in Modern Construction

Beyond performance and aesthetics, modern construction places a strong emphasis on sustainability. Choosing materials from an environmentally conscious PU Insluation ceiling factory aligns with the principles of green building. The primary environmental benefit of PU insulation is its profound impact on a building's energy efficiency. By drastically reducing the energy required for heating and cooling, these ceilings lower a building's carbon footprint for its entire lifespan. Furthermore, leading manufacturers are committed to responsible production, often incorporating recyclable materials into their products to minimize environmental impact. This ethos of producing eco-friendly building materials ensures that your project is not only built to last but is also built with respect for the planet.

Partnering for a Better Build: The Final Word

In conclusion, PU insulated ceiling panels represent a harmonious blend of technology, design, and sustainability. Their superior thermal resistance, structural durability, and versatile applications make them an exemplary choice for modern construction projects. However, the key to unlocking these benefits lies in the partnership you forge. By carefully selecting an expert PU Insluation ceiling manufacturer and a dependable PU Insluation ceiling supplier, you ensure your project is built with materials of the highest quality. This strategic decision guarantees enhanced energy efficiency, long-term performance, and a final result that stands as a testament to innovation and excellence in construction. Elevate your next project by investing in a solution that delivers on every front.